- Home

- Seals

- PTFE

- CONTACT

- ABOUT

- SOLUTIONS

- NEWS

Polytetrafluoroethylene (PTFE) is a high molecular weight fluorocarbon consisting wholly of Carbon and Fluorine. Discovered by Roy Blunkett in 1938, it was Patented by Kinetic Chemicals in 1941 and trademarked Teflon in 1945. Originally used in Aerospace and other Hi-tech applications, the generic PTFE polymer has been developed so that it is now used across a broad range of industries.

Gapi process by two polymerisation methods:

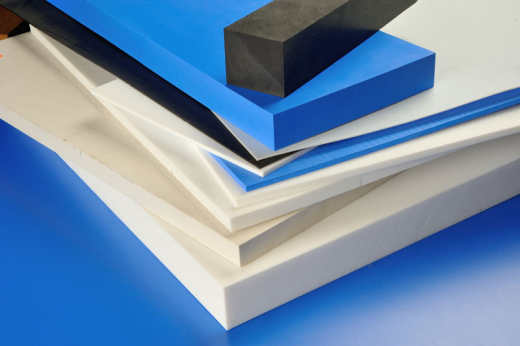

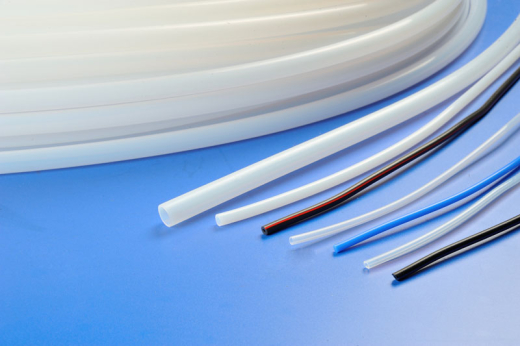

• Granular PTFE from suspension polymerisation to form Rods, Sheets and Tubes

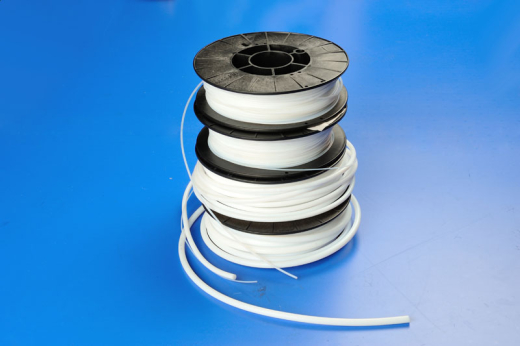

• Fine PTFE coagulated powders from dispersion polymerisation to produce Thin Wall tubing.

The unique properties of PTFE means it is now used across many different market sectors, for example O Rings, Seals, Washers, Plain Bearings, Gears, Slide Plates, High Voltage Switchgear, Electrical Sleeving, Chemical Dosing, etc

PTFE offers

• Excellent thermal resistance

• Excellent resistance to both chemical and solvent attack

• Low co-efficient of friction, thus high anti-stick properties

• Excellent dielectric properties

• Excellent arc resistance

• Approvals for use in food and potable water applications

Our filled PTFE range can enhance these properties improving wear characteristics, deformation under load, thermal stability and offer anti-static options.

As one of the world’s largest PTFE processors Gapi offers a huge range of sizes from stock at our UK base in Rotherham.

Gapi is an ISO 9001:2015 registered company.

Gapi processes PTFE in its Lanza factory, the oldest PTFE production facility in Italy, which is constantly being updated by investment in the latest advancements in technology to increase the range and improve best practice in the production process.